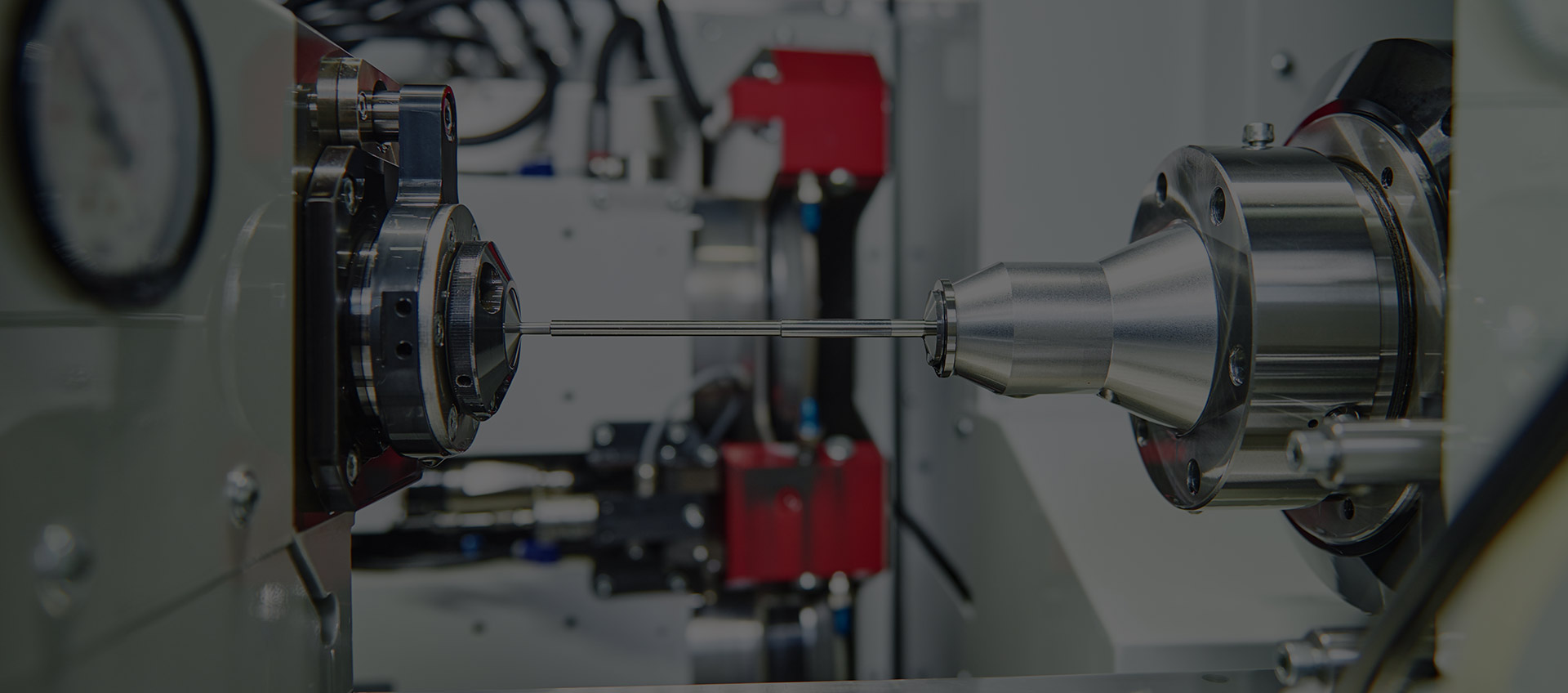

CNC Turning & Milling

For over 15 years, Tychon, Inc., has been supplying precision CNC machined parts to customers nationwide. We operate a full-service machine shop and leverage the newest advancements in CNC milling and turning technologies to produce close tolerance parts in prototype to production volumes.

Exceptionally proficient at producing parts with detailed geometric forms, thin-walled sections, and complex curves and angles, we operate a fleet of milling and turning centers with different work envelopes, automation features, and process capabilities. Our production assets include programmable 3- and 4-axis CNC equipment with live tooling, automated bar feeds, and other productivity features. We can machine parts as large as 15.0″ in length x 20.0″ in width x 4.0″ in height, or with a maximum diameter of 7.0″ while upholding tolerances as tight as ±.0002″. Along with aluminum, alloy steels, bronze alloys, stainless, and many other metals, we manufacture parts from plastic polymers and other non-metals, such as composites.

We perform both in-process and final inspections. Through the entire machining cycle, we continually measure and monitor quality metrics to ensure there are no deviations and your finished products conform exactly to your specifications. As part of our end-to-end production capabilities, we offer various heat-treating and finishing options. We also have the skills and staffing to provide you with fully assembled products.

As a reliable manufacturing partner, we provide quality parts, deliver them on time, and our pricing is fair and competitive. Our customer service team is responsive and always available to answer your questions or provide you with information. We provide precision quality, high-performance components that comply with Mil-spec, SAE, and other industry standards. Contact us today to discuss your project or request a quote.

Machining Processes

Milling

Drilling

Boring

Turning:

- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

Threading

- External

- Internal

Tapping

Thread Milling

Internal Forming

Knurling

Counterboring

Countersinking

Pocketing

Profiling

Reaming

Parting/Cutting

Facing

Hard Turning

Equipment Capabilities

Lathe

- Engine

- CNC

- Live Tooling

Mill

- Vertical

- Conventional

- CNC

Equipment

- 2004 FADAL VMC 15-XT CNC machining center – travel X-30″/ Y-16″/ Z-20″

- 1999 FADAL VMC-3016 HT CNC vertical machining center – travel X-30″/ Y-16″/ Z-20″

- 1992 FADAL VMC-3016 CNC vertical machining center – travel X-30″/ Y-16″/ Z-20″ w/ Fadal CNC 4th axis indexer

- 2011 Hardinge GX 1000 VMC w/OSP Control – travel X-40.16/Y-21.25/Z-21.25

- 2007 Okuma Heritage ES-L8 CNC lathe with tailstock – 8″ chuck, and 2″ bar through spindle

- 2008 Okuma Heritage ES-L8 II CNC lathe with tailstock – 8″ chuck, and 2″ bar through spindle

- 2010 Doosan Daewoo Lynx 220 LM CNC lathe with tailstock – C-axis milling capability, 6″ chuck and 2″ bar through spindle

- 2010 LNS Eco Load short magazine bar feed

- 2006 FADAL VH5C rotary head with servo control

- 2007 LNS Quick Load Servo 65 bar feeder – ¼”-2-5/8″ bar stock diameter

- 2004 VICTOR JF2VS knee mill with Newell digital readout and “X” axis power feed – travel X 49″ / Y 24″

- 2004 VICTOR 1440B Lathe with 5C collet closer and Newell digital readout- 8″ chuck, / 36″ between centers

- VectraX gear drive saw

Inspection Equipment

36″/48″ Inspection grade surface plate

Electronic Micro Heights

Gauge Pins

Bore Mics

Rockwell Hardness Tester

Machinery Axis

3

4

Live Tooling

Fixturing

Three-jaw chuck

Four-jaw chuck

In-House Fixturing & Tooling

Part Diameter

7″

Part Length

15″

Part Width

20″

Part Height

4″

Maximum Part Weight/Maximum Lifting Capacity

50 LBS

Tolerances (+/-)

.0002″

Materials (Metals)

Alloy Steels

Aluminum

Beryllium

Brass

Bronze Alloys

Carbon Steel

Copper

Iron

Magnesium

Molybdenum

Stainless Steel

Tin

Titanium

Materials (Plastic Polymers)

ABS (Acrylonitrile Butadiene Styrene)

Acetal

Acrylic

Fiberglass Reinforced Plastics

Nylon

Polycarbonate

Polyetheretherketone (PEEK)

Polyethylene

Polypropylene

PTFE (PolyTetraFluoroEthylene)

PVC (Polyvinyl Chloride)

Teflon

Materials (Other Materials)

Composite Materials

Fiberglass

Graphite

Wood

Secondary Services Offered

Assembly

Drilling

Tapping

Threading

Counter Sinking

Pressing

Reaming

Plating

Passivating

Heat Treating

Anodizing

Production Volume

Prototype

Low Volume

High Volume

Blanket Orders

Lead Times

Quoted on job by job basis

Emergency services available

Rush Services Available

Additional Information

Industries Focus

Amusement Parks Components

Aerospace

Architectural

Automotive

Construction

Electronic

Food

Machine Tool

Marine

Medical

Military

HVAC

Hotel

Imaging

Oil/Gas

Optical

Robotics

Inspection Equipment

Industry Standards (Compliance)

ANSI- American National Standards Institute

ASME –American Society of Mechanical Engineers

ASTM –American Society for Testing and Materials

ISO- International Organization for Standardization

Mil-Spec- Military Specifications

SAE- Society of Automotive Engineers

File Formats

AutoCAD (DWG, DWZ)

BMP – Bit Mapped Graphics

DXF – Drawing Interchange Format, or Drawing Exchange Format

GIF – Graphics Interchange Format

IGES – Initial Graphics Exchange Specification, ANSI file format.

JPG or JPEG – Joint Photographic Experts Group

MasterCam (MDX, MC8, MC9, SET)

PDF – Portable Document Format

Pro-E or Pro/Engineer (DRW, PRT, XPR)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)