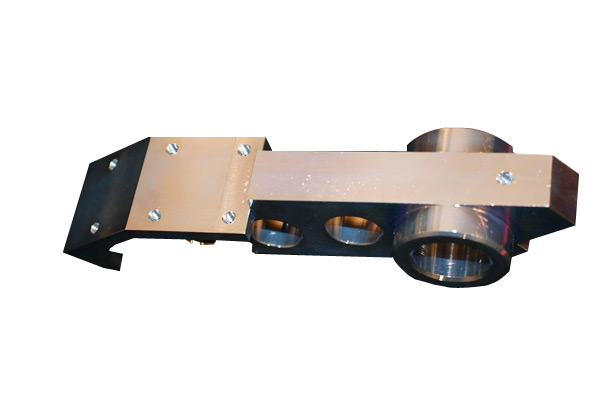

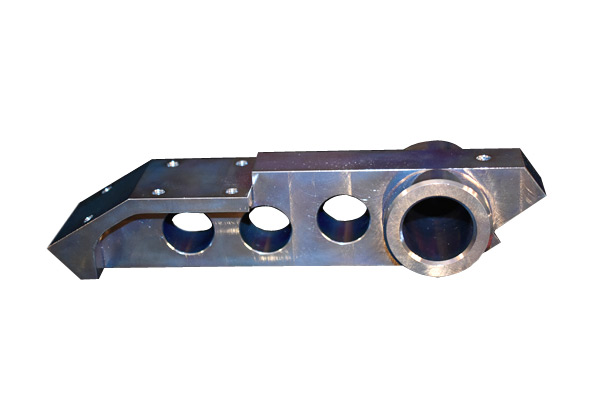

Retainer Dog

When safety is a critical issue, customers know they can count on our Orlando CNC shop to manufacture parts that consistently perform to the highest standards.

Tychon, Inc. proudly manufactured the zinc-plated retainer dog pictured here for a customer in the amusement park industry. With very tight tolerance requirements of ±0.0005” on the finished product, our challenge was to consistently attain the correct machined dimensions to accurately account for the plating thickness. In addition, we had to maintain tight control of the plating process to ensure we achieved the correct level of plating thickness, which is typically measured in the single digit micron range.

Production in our machine shop involved 3- and 4-axis milling to form the geometric shape and create the detailed features of this complex, precision-engineered part, which featured dimensions of 1-3/4” in length x 1-3/4” in width x 7-1/2” in height. We designed and built a customized fixture to perform 4th axis milling process. Since this was a technically precise application, we machined the part from AISI 1018 cold rolled steel, a mild low-carbon grade with a good balance of strength and toughness. The properties of cold rolled steel promoted quality, allowing us to machine the part with close tolerances.

Additionally, we had zinc plating – per ASTM B633 Type III standards – applied. This particular finish provides cost-effective corrosion protection and consists of zinc plating followed by a chromate coating to increase the protective qualities. Our rigorous quality control procedures incorporated a series of dimensional measurements using instruments such as calipers, bore micrometers, gauge pins, and others.

From start to finish, this project took us five weeks to complete. The client was impressed with our ability to maintain consistent, close tolerances. If you have a similar part and would like to learn more about our precision CNC machining capabilities or request a quote, contact us directly.

RETAINER DOG HIGHLIGHTS

Project Name & Description

Retainer Dog

Capabilities Applied/Processes

3 & 4 axis milling

Equipment Used to Manufacture Part

CNC Mill

Overall Part Dimensions

1-3/4″ X 1-3/4″ X 7-1/2″

Tightest Tolerances

(+/-) .0005

Material Used

AISI 1018 CR

Material Finish

Zinc plate per ASTM B633 Type III

Industry for Use

Amusement Park

In Process Testing/Inspection Performed

Caliper, bore mic, gage pins, thread gages

Volume

5-25

Delivery/Turnaround Time

5 Weeks

Delivery Location

Florida

Standards Met

As per customer specifications